Explosive Atmospheres within the Food Processing Industry

Are you operating with products that can potentially be Explosive?

Explosive Atmosphere – Ex – IECEx – ATEX – Zone 1 – Zone 2 are you and your team familiar with what Zone you are operating in or what products are classed as Explosive?

Compliance to the directives for your country is essential.

The most common products associated with Explosive environments are:

Þ Flour Mills, Confectioneries, and Bakeries – Þ Cereal manufacturers – Þ Spices & Flavorings in bulk forms – Þ Egg & Milk Powders – Þ Salts – Þ Powered Sugars – Þ Coffee Manufacturers – Þ Distilleries / Alcohol – Þ Oil Processing – Þ Flammable Liquids / Essences – Þ Starch – Þ Stabilizers – Þ Nuts or Powdered Nuts

Note; Explosive environments can relate to the transportation, processing or storage of products and ingredients.

Some equipment may require additional grounding and the use of complete Anti-Static Workwear/ Footwear, and Anti-Static Flooring as certain products build up static during production.

Do you have a Explosive Atmosphere management plan?

Classifications and Zoning of Explosive Atmosphere Areas.

Identify, classify and segregate the Explosive Atmosphere Areas at your site.

Classification will be dependent on your Countries requirements, the size of your facility and level of products classified as Explosive, along with the risk level of an Explosion.

Ensure all team are aware of the Explosive Atmosphere Area and ensure that those that are equipped for working in that area enter that workspace. Those approved for entering the area are to be wearing correct workwear/footwear and are familiar with the correct equipment that has been designed for Explosive Atmospheres.

Clear Signage of an Explosive Area is required, “you are entering an Explosive Atmosphere” and “are you wearing required workwear” and “are you using the correct equipment for this area”, these are just a few phrases that are being used in Explosive Atmosphere areas.

Explosive Atmosphere Safe Equipment.

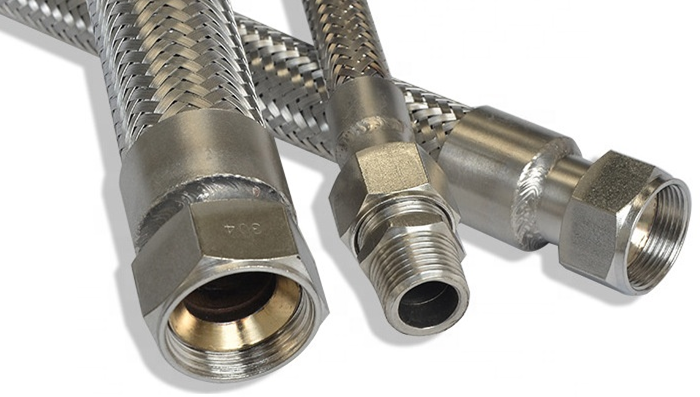

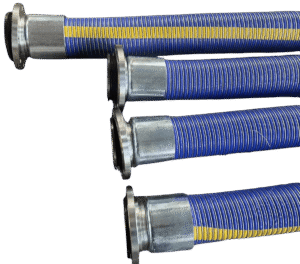

Depending on the type of processing being conducted it will depend on what equipment is required. What we are looking for is Ex ESD Equipment, this is equipment that is specially designed not to create any sparks, ESD stands for Electrostatic Discharge. If you have an Electrostatic Discharge occur or commonly know as sparking, this creates an ignition thus creating an explosion. You do not want any sparks created in your facility? Flammable liquids or powders?

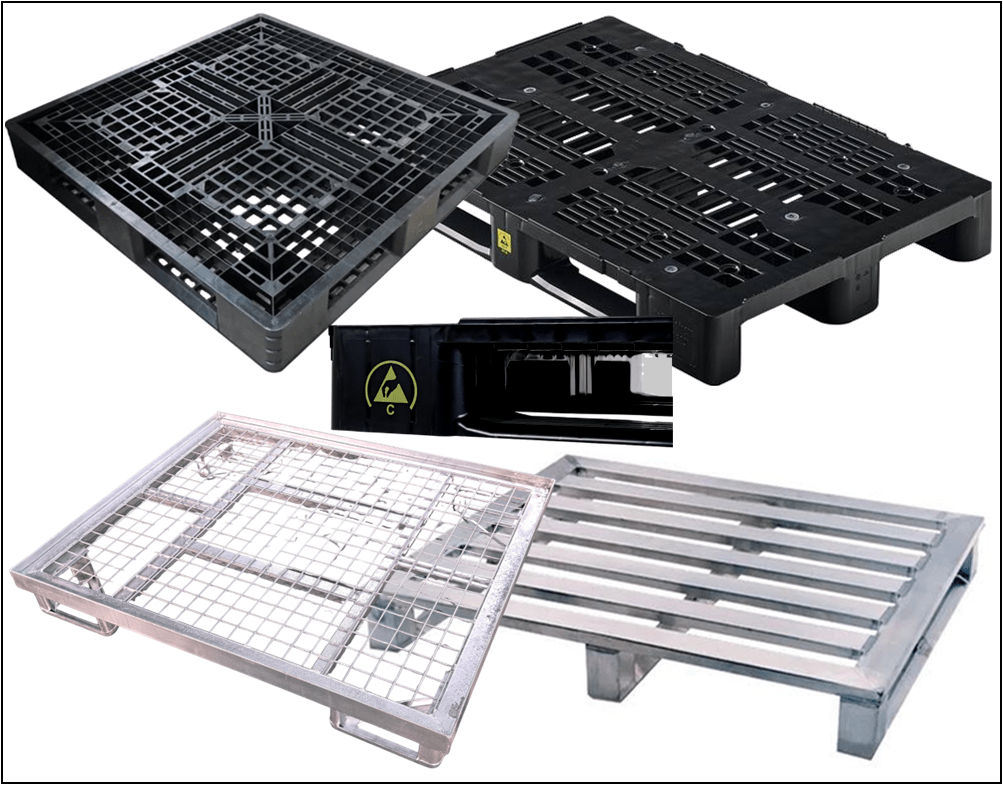

Train the team as to what and how equipment can create sparks. As an example a common timber pallet that has steel nails in it is a hazardous product, a nail can drag along the ground creating a spark and the timber can catch on fire, only ESD or Aluminium pallets should be used in an Explosive Atmosphere Area. Standard Plastic Pallets also are not suitable for Explosive Atmosphere Areas as the plastic can create static build up, thus creating a spark within the static. An ESD Pallet has carbon fibre mixed in with the plastic mix, this creates an Anti-Static Pallet

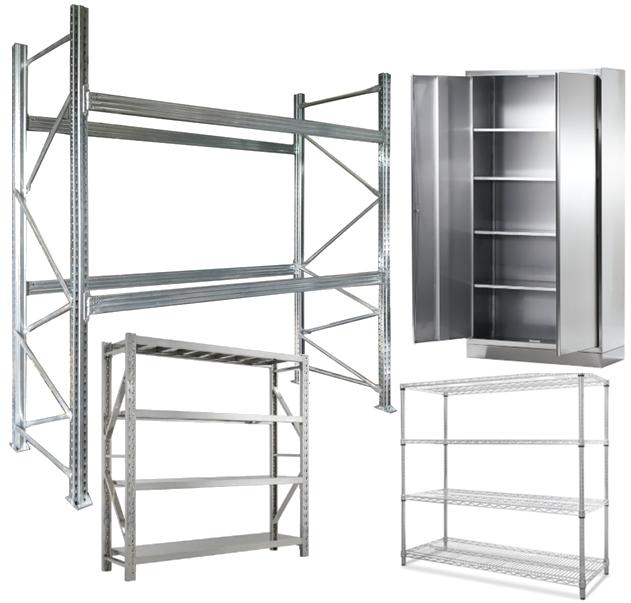

Equipment for Explosive Atmospheres include but not limited to: Benches, Trolleys, Containers, Pots, Forklifts, Pallet Trucks, Brooms, Brushes, Scoops, Spatulas, Scrapers, Squeegees, Buckets, Tube Brushes, Shovels, Step Stools, Drum Lifters, Maintenance Tools- Spanners, Wrenches, Hammers, Sockets, Hex-Keys, Vacuum Cleaners, Compressors, Drum Taps, Scales, Lighting, Dust Extraction, Control Panels, Pumps, Filters, Conveyors, Packaging, Gloves, Shelving, etc.

Note: Equipment for Explosive Atmosphere may not be available in colour coded products that you may be used to within the Food Processing Facility, this is due to the manufacturing process of Explosive Atmosphere Equipment there is additives used in the manufacturing process, that if colorings are added for colour coding it will reduce or compromise the strength of the product, or counteract the Anti-Static properties.

Continuous Training and Support of your Team.

Training in an Explosive Atmosphere is of utmost importance, after all the Explosive Atmosphere Area is the catalyst of safety for the entire facility. Ensure all team members including the call-ins are familiar with the requirements within your Explosive Atmosphere Area. Without being prejudice it may be wise to screen who has access to this high pressure area, due to those who cannot operate at fully compacity when under pressure emotionally and physically.

You will require Team Leaders for the Explosive Atmosphere Area to establish a clear system for control.

Awareness Signage / Visual Management, Clear Signage for awareness of Hazardous or Explosive Area to assist your team and visitors is required.

Continuous Training ensures any new team members are fully aware of protocols in place for the Explosive Area.

Directives for Hazardous or Explosive Areas in your facility.

Facilities are required to know what their hazardous products are, and whether it is operating with potentially Explosive products in the facility, so that you can adhere to the guidelines set out by the Directives for your country, ATEX or IECEx Directive. Confer with your local Health & Safety Executive, this will provide you with peace of mind that you are doing all you can to provide a safe environment for your team.

Strategy to staying safe.

Identify, classify and segregate the Explosive Atmosphere Areas at your site.

Explosive Atmosphere Equipment.

Continuous Training.

Awareness Signage / Visual Management.

Clear system of control.

Visual Management has no language barriers!